Data Visualisation – 5 Ways to Easily Improve Your Operations

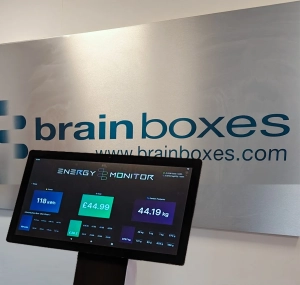

Written by Brainboxes

Wherever you are on your digital transformation journey, data visualisation makes it easy to optimise operations.

Wherever you are on your digital transformation journey, data visualisation makes it easy to optimise operations.

Big Data – shorthand for the billions of transactions datasets generated daily – is key in industry, but simply collecting reams and reams of counts and figures isn’t enough. The data must of course be accurate and relevant. Moreover, it’s vital that it can be analysed in the right way to enable businesses to make the best data-driven decisions.

The actionable insights are already there, contained in the data. Data visualisation – viewing information in clear graphical forms – takes the guesswork out of analysing big data by cutting out the noise and making it easier to spot trends, patterns and unusual values (outliers.) Often complex statistical analysis isn’t required; simple data visualisation allows humans to understand the big picture unclouded by individual data points.

Data visualisation can gather data from different sources and show it graphically in one place, making it easier to identify organisational opportunities, shine a spotlight on inefficiencies, and help solve other common challenges on the factory floor.

1. Reduce costly errors

To err is human; the ability to spot inevitable mistakes in real-time and respond quickly can make a huge difference.

Using data visualisation to show data from varied sources on a centralised visual dashboard allows supervisors to see everything at a glance (shift productivity, machine downtime, outputs, etc.), making it easier to keep track of every part of the manufacturing process and action fast responses.

2. Streamline the supply chain

Data visualisation means you can take data at any given time, and compare it against historical performance data. With historic data visualisation, it’s easier to track ROI and delivery rates, identify where resources are allocated, and manage Overall Equipment Effectiveness to optimise supply chain efficiency.

3. Balance quality control with cost-cutting

A visual data model makes it easy to see where resources are spent and proactively identify potential flaws; ensuring that all processes are designed to meet quality assurance standards in the most cost-effective way. Quality doesn’t always have to come at a price; some of the largest quality gains can be made by simple changes highlighted by data visualisation.

4. Identify & eliminate inefficiencies

Enterprise Resource Planning (ERP) is the measurement and management of critical processes, often in real time. Data visualisation lets you discover datasets related to resources, materials, productivity, and shift performance in a comprehensive database. This will enhance ERP, allowing decisions to be made more rapidly and with fewer errors.

5. Data visualisation with free open-source software

Even without the facilities to capture data, it’s possible to prove concepts without wiring sensors, by using free-to-start, open-source software (InfluxDB and Grafana) and Brainboxes BB-400 Industrial Edge Controller.

In industry, it’s common to count how often something changes, store the information, and then review and analyse the information in a graph. For example temperature, parts counts, or machine errors. Node-RED can be used to send data to InfluxDB which can then be visualised in Grafana.

Watch the video above for an easy-to-follow tutorial, that will walk you through sending data from an edge controller to a database in InfluxDB and how to produce graphical visualisations of the data.

Find the original article here

Leave a Reply

Want to join the discussion?Feel free to contribute!