Written by Chen Zhang

With Single Pair Ethernet (SPE) gaining more attention in industrial automation, it’s important to understand the potential benefits this technology can bring to applications that need to transmit data across long distances but don’t have extensive speed or bandwidth demands.

In a recent blog, we discussed how the industry is overcoming hurdles to Single Pair Ethernet deployment. Now it’s time to highlight the concrete advantages of replacing a four-wire line with a two-wire line in regard to cost, installation and performance so SPE can confidently be used in practice.

1. Lower Capital Expenditures

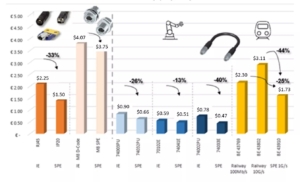

In the figure below, you see the price that’s typically paid for an Industrial Ethernet (IE) connector on the left. On the right, you see the corresponding Single Pair Ethernet connector and its price.

IE and SPE connectors are quite similar to today’s RJ45 and M8 D-coded connectors. Although three-quarters of the wires are eliminated in an SPE connector, additional filling material is used to maintain the cable’s round shape. Depending on the type of cable used, cost savings between IE and SPE connectors span from 13% to 44%. Additional savings kick in when connectors are purchased at higher quantities.

In terms of capital expenditures, however, the most significant savings come from the new network topologies that are possible with Single Pair Ethernet. For example, eliminating gateways and relying on a single communication network can save more than $10,000 per gateway. SPE makes it more economical to integrate sensors and actuators into network infrastructure.

Capital Improvement: Single Pair Ethernet vs. Industrial Ethernet

2. Weight Savings and a Small Footprint

Single Pair Ethernet technology allows for more compact, lighter cables that offer 50% less weight and a 50% smaller footprint than traditional fieldbus cables. This saves valuable space within robots and inside walls and floors.

Let’s use electric vehicle production as an example of these savings. Design engineers are looking for ways to remove every ounce of weight from the chassis to offset the weight of power systems like batteries and electric motors. For instance, some designers have explored the removal of shielding material in cable harnesses inside cars to reduce weight. SPE presents a potential solution for weight reduction in electric vehicles.

Single Pair Ethernet pays an essential role in the retrofit of electric vehicles, too. It’s recommended that, every 10 years, vehicles return to the factory for a refurbishment of essential electronics. The construction of the chassis will not change, so the thickness of the wall within the car remains unchanged. SPE cable can reduce the amount of space required for installation. This weight advantage is in addition to port density (two SPE ports = 1 RJ45 port), which supports more devices in older vehicles.

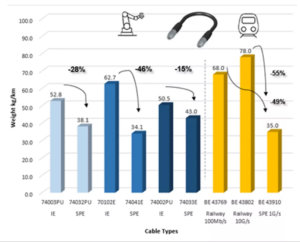

The figure below compares the weight of different SPE cables to the weight of conventional industrial Ethernet cables—and the savings between the two cable types. You’ll notice savings of between 15% and 46% on Ethernet cable types used in discrete manufacturing; in cable types used in transportation, savings of between 49% and 55% are common.

Weight Improvement: Single Pair Ethernet vs Industrial Ethernet

3. Fast Installation and Easy Maintenance

SPE supports faster, easier installation by allowing field devices, sensors and actuators to be easily integrated into existing Ethernet environments with no additional gateways and interfaces.

This drives material and labor costs down for new factory floor builds.

4. Simplified Networks

Single-Pair Ethernet (SPE) can bring automation systems and legacy industrial networks on to a single Ethernet network technology while carrying power and data to and from devices.

Because they’re based on Ethernet protocols, the performance of SPE devices is generally better than fieldbus devices.

Migrating sensors and controls to Ethernet using SPE simplifies cabling and management and potentially eliminates specialized networking equipment, bringing IP communication to the lowest levels of automation.

With SPE, troubleshooting and failure diagnostics become more standardized and accessible compared to the mixture of fieldbus protocols and special decoders and terminals that are required by even the most exceptional skilled technicians in order to address performance issues.

5. Support for IT/OT Convergence and Sensor to Cloud

The industrial environment of the future requires flexible and adaptable connectivity that can accommodate increasingly growing demands.

SPE is one of the technologies that will contribute to IIoT, Industry 4.0, IT/OT convergence and seamless data transmission from field-level sensors to the cloud. These innovations come together to create smart manufacturing environments—driven by Single Pair Ethernet.

6. Environmental Friendliness

Finally, SPE requires fewer natural resources, like plastic and metals, to build Ethernet-based infrastructure and connect assets, helping companies reduce their carbon footprint and achieve ESG goals.

Our Single Pair Ethernet Portfolio

Our Single Pair Ethernet portfolio of cabling and connectivity products is designed to optimize Ethernet connection possibilities in harsh environments, including industrial and transportation operations.

As Industry 4.0 evolves, and the number of sensors and actuators connected to the factory backbone continues to grow, Single Pair Ethernet will be a simple solution that accelerates industrial automation.

Find the original article here